Chemical Latent Development

Guide to Selecting a Latent Fingerprint Development Method based on Surface Type

| Surface | Treatment Method |

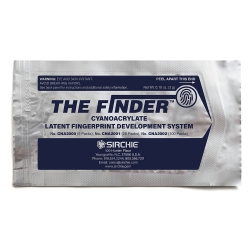

| Smooth, non-porous: glass, hard plastic mouldings, surfaces treated with paint or varnish | Powders, iodine, small particle reagent (SPR), cyanoacrylate/fluorescent dyes |

| Rough, non-porous: rough, textured surfaces, grained plastic mouldings | Small particle reagent (SPR), cyanoacrylate/fluorescent dyes |

| Paper & cardboard: paper & cardboard that hasn’t been waxed or plastic-coated. | Iodine, ninhydrin, DFO, silver nitrate, or physical developer. Powders won’t work with older fingerprints |

| Plastic packaging media: Polyethylene, polypropylene, cellulose acetate, and laminated paper surfaces | Iodine, small particle reagent (SPR), cyanoacrylate/fluorescent dyes, and powders |

| Soft vinyl (PVC), rubber and leather: simulated leather and cling film | Use iodine, small particle reagent (SPR), cyanoacrylate and powders. |

| Untreated metal: untreated, bare metal surfaces; metal surfaces that haven’t been painted or lacquered. | Small particle reagent (SPR), powders, cyanoacrylate / fluorescent dyes and powders |

| Unfinished wood: wood surfaces that haven’t been painted or treated. | Ninhydrin. You can use powders on smooth wood and silver nitrate or physical developer on light woods. |

| Wax and waxed surfaces: items made of wax, such as candles, wax-coated paper, cardboard, wood surfaces | Nonmetallic powders, cyanoacrylate / fluorescent dyes |

| Adhesive-coated surfaces: tapes and similar surfaces that are not likely to dissolve in water | Adhesive-side powders |